Electromagnetic grain refinement casting technology for large size ingots of high strength aluminum and magnesium alloy

The Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education,P. O. Box 314, Northeastern University, Shenyang, People’s Republic of China

What is high strength aluminum alloy?

* Yield strength more than 500MPa;

* Al-Zn-Mg and Al-Zn-Mg-Cu serials(7xxx);

Problems in large size ingot production of high strength aluminum alloy

a. easy to crack

b. coarse grains and inhomogeneity structures

c. bad cast surface

Principle of electromagnetic grain refinement casting

Principle

1. A group of induction coil is configured on the peripheral of ingot, and then the coil is applied with low-frequency alternating current.

2 The aluminum melt can be stirred by Lorentz force.

3 Easy to implement, need not any change in casting machine, only need a new mold.

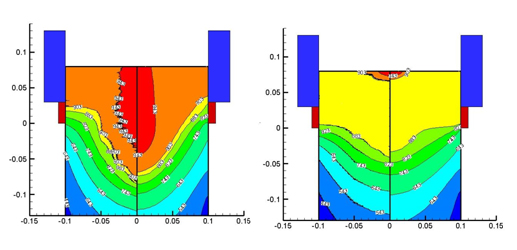

Flow pattern

Left: without electromagnetic field;

right: with electromagnetic field

Temperature field

Left: without electromagnetic field, high temperature gradient ;

right: with electromagnetic field, low temperature gradient ;

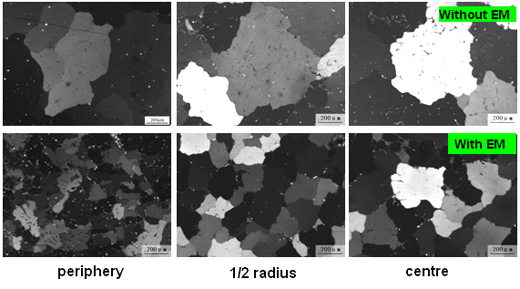

Microstructure of 7xxx alloy

Left: without electromagnetic field, dendritic and coarse;

right: with electromagnetic field, spherical and fine;

Distribution of alloy elements in electromagnetic grain refinement casting ingot, macrosegregation is alleviated.

7050 aluminum alloy ingot(φ500mm)

7050 φ500mm ingots microstructure

AZ31magnesium alloy ingot product by electromagnetic grain refinement casting, AZ61, AZ91can be product also.

billet : 300-400(thick)X800-1000(wide) 800 ingots Largest magnesium ingot in the world

|